Why Do you Need to Train your Factory Workforce?

9 minutes read

The most experienced and knowledgeable manufacturing workers are retiring. The business leaders in the manufacturing industry are facing challenges to fill the positions that the senior workers are vacating. Because there aren’t enough people with the right set of skills and training who are willing and able to take these jobs.

Some of the key reasons are

Education gap between the industry requirements and the expertise in the applicant pool.

Graduates coming into the industry lack basic skills

This gap is further increased by the increasing adoption of digitization in the factories

Call it Industry 4.0 or smart manufacturing, the equipment and environment in a lot of manufacturing plants are getting very technical, very quickly. But are the workers suitably trained to work in these new-age factories?

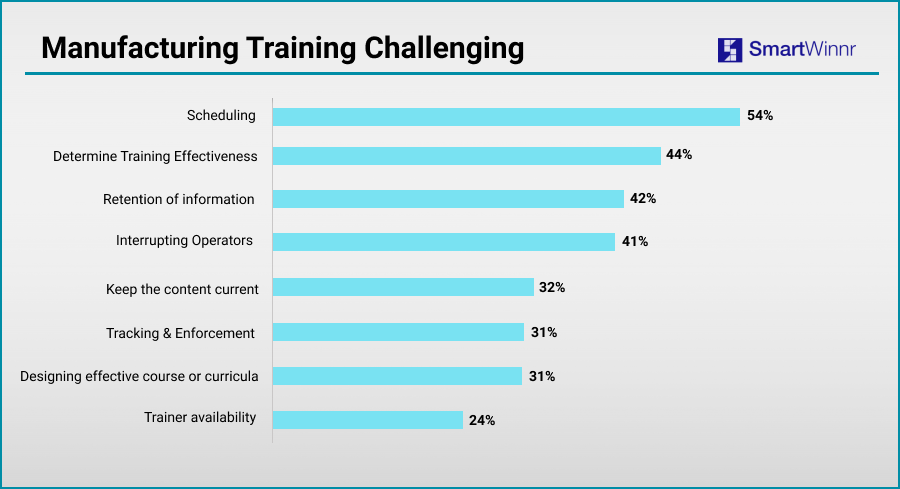

To address these concerns surrounding the skill gap and worker shortage in the manufacturing community, Industry Week conducted a survey to determine the state of manufacturing training in the U.S.

Here are some facts of manufacturing training that came to light from that survey:

Training Methodology

Nearly three-quarters (72%) of the companies responding to the survey still rely on traditional shadowing or on-the-floor training methodologies

Only 39% of respondents indicated heavy use of classroom education.

Only 10% of them use outside consultants to supplement their training curriculum or its delivery.

The average new operator receives just 18 days of training and a full 40% of these people are trained for a week or less. This is not enough or the right kind of training to reduce the skill gap

Digital Tech in Training

- About 50% of the respondents said that they use videos and digital files in their training There is a noticeable lack of high-tech digital supplementation like online training.

Trainer’s Efficiency

On-the-floor training is delivered by experienced operators. While this is valuable, it also has certain downsides like,

Reduced productivity of the operators as training is peripheral to their “real” job.

Not all experienced operators can be effective teachers or mentors

Training varies from one training operator to the other. If different operators train different batches of new recruits then what one batch learns can be different from what another one learns. The amount and depth of knowledge received by recruits may also differ. This leads to non-uniformity in knowledge levels amongst the workers.

Training Content

Most companies spend less than 5 hours a week creating training materials. They generally update the training content only when absolutely required. As a result, the latest information is not available to the trainees at all times.

Most respondents said they do not have the resources to create the necessary content for training.

Knowledge Retention

- The trainees are unable to retain the information that is passed on to them while training on-the-floor. So, it is difficult to understand if this training is effective in the first place.

The good news is that most companies do recognize the importance of updating their training programs. Sure they are struggling with time and resources. But they know they are out of alignment with the modern training needs and they are beginning to look for solutions/fixes.

A Better Way to Train

While on-the-floor training is not going away anytime soon, there are ways to supplement it and make it better. You need to ask yourself these questions in order to make your training better:

How can you make sure that the employees aren’t overloaded with the information during training?

Is there a way your employees can have the information they need after training?

Here are the solutions that address the above questions:

1. Digitize the training material

Written training materials are not ideal for sending important instructions across to your workers. In the case of machine repairs or specific tasks, it is very difficult to create good instructions on paper.

It is even more difficult for your trainees to understand from the written instructions. Apart from this, they won’t be able to refer to that information immediately at the time of need.

Convert the training material into digital content like PDFs, PPTs, videos, etc. This allows you to present the information in various creative and visually appealing formats. This makes it easy for your trainees to grasp and apply the instructions.

2. Create Microlearning Content

It’s extremely difficult for your trainees to digest hours of on-the-floor training or lengthy PDFs/ PPTs in one go. So, we suggest that you instead create micro-learning content.

Break down your lengthy training PDFs/ power-point presentations into shorter videos (2-3 minutes), infographics, or storyboards. The content could be segmented topic-wise like quality, maintenance, safety, resetting, etc. This kind of microlearning content, which presents to-the-point information, makes it easy for the trainees to learn it quickly and easily.

3. Just-in-time learning

Make this digitized microlearning content available to your trainees on their mobile devices or tablets. This enables them to access and learn a piece of information anytime and anywhere they want.

Pro-tip: Here is an ideal way to present equipment/ machine-related instructions: Create a system where the operator or trainee can directly go to a machine and scan the QR code on it. This should take them right to that piece of training content or videos related to that machine. This way a worker need not even know the name of the machine. He can directly learn about it using a QR code.

Who Will Create the Training Content?

Creating training content is another significant challenge that organizations face. Create a structure and framework around that.

Select your most experienced operators who are also good at training. Create a SWAT team with them. Get this team to create and frequently update the knowledge base as time permits. They should be responsible for creating and maintaining all the training content including machine instructional videos.

To create these videos, someone with a smartphone or tablet can actually film the expert explaining various tasks. These videos should then be made available to the trainees during and after their training. They should have these videos continuously available with them so that in 6 months’ time they could watch it again if they needed to do a task that is not within their normal scope of operation.

Pro-tip: These videos also help in capturing tribal knowledge. For instance, you can create a system where, if a problem comes up, the expert can create a video with the solution. This video should then be matched to the relevant equipment or process. This way people can discover any solution they need at any point in the future. It creates a reliable process of capturing the knowledge, sharing it, and making it easy to apply.

How to Motivate the Operators to Create the Content?

It’s crucial to recognize that your operators are taking time out of their already busy routine and making the extra effort of updating the knowledge base from time to time. So, you need to motivate them to keep up this good work.

Gamifying is the best way.

Create a competition around creating and uploading the instructional videos. Every time an operator uploads a video he will be awarded 100 points. At the end of each month, add up these points, and calculate the total score of each operator. Then, reward the one with the highest score. This will motivate your operators to upload more number of videos. This will ensure that you get a significant number of video submissions.

In order to ensure that you get quality submissions, run a competition around creating the best videos. Your trainees can like the videos which they find most informative. Then, at the end of each month, reward the operator whose video has received the highest number of likes.

This way you will be able to effectively motivate your operators to regularly create the best content.

Conclusion

The challenge of a shrinking workforce and skills gap may seem insurmountable. But developing new and more effective training mechanisms can go a long way toward making the process less expensive and painful.

Want to know more about microlearning?

Microlearning- An effective way to train millennials

How to Convert a PowerPoint Presentation into Microlearning Content?

Want to run exciting contests for your manufacturing workers?

5 Amazing Contest Ideas for Manufacturing Units

Contest Names for Manufacturing

Looking for a platform to automate the process of delivering microlearning feeds to your learners?

Explore SmartWinnr’s SmartFeeds. SmartFeeds help you create microlearning feeds and deliver them to your learners through the SmartWinnr mobile app regularly. Your learners can then like and react to these feeds. This helps in increasing the engagement of the learners.

Interested to see it in action? Book a demo today!

Published on Fri Oct 16 2020